Sign up, browse, and watch our training classes on-demand 24/7 at our MMUS Newsstand. You can watch one or binge-watch our complete training class offerings at your convenience. A certificate will be issued with each training class upon successful completion. Click Here for access to the full library.

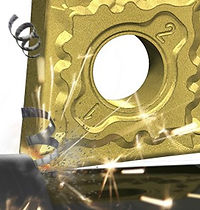

Turning Grades & Geometries

Join us for an in-depth look at our Turning grades and Geometries. We will discuss the difference between CVD, PVD and Cermet grades to better understand where to apply them. Along with an explanation of our grade nomenclature and in what ISO material group each series of grades should be applied. Click on the button below to enroll.

Catalog C010A

In this webinar, you will learn how to navigate our catalog. Our product line is extensive and continues to expand. Whether using the print version, PDF, or web catalog, we’ll show you how to effectively find product nomenclature descriptions, size offerings, speeds and feeds, spare parts, technical data, and even more resources. Click on the button below to enroll.

Solid Carbide Drilling Features

In this webinar, we examine the features of our Solid Carbide Drill product line. We will discuss flute length, point angles, and the different types of cutting edge geometries. Through a better understanding of these features you will be better equipped to maximize the machining of your applications. Click on the button below to enroll.

Basics of Turning Part 4: Cutting Resistance, Cutting Conditions, Speed and Feed Calculation and Work Holding

In Part 4, the final session of the Basics of Turning webinar, we’ll cover a range of topics including cutting resistance, cutting conditions, speed and feed calculations, and work holding. By the end, you’ll be ready to apply this knowledge to boost both efficiency and quality at the machine. Click on the button below to enroll.

Solid Carbide End Mills

In this webinar, we look at our solid carbide end mill product lines to gain a better understanding of their features and benefits. We will also provide instructions on how to utilize them to overcome challenging machining needs in specialized industries. Click on the button below to enroll.

GY/GW Series: Part 1

In Part 1 of the GY/GW Series, we will cover nomenclature descriptions to aid in the selection of the proper tooling. An explanation of insert chip breakers and grades, which will include how to find and read cutting speeds, along with the best operating practices for the GY Series. Click on the button below to enroll.

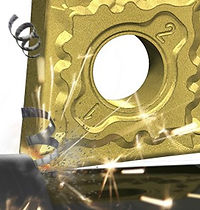

Basics of Turning Part 2: Functions

& Geometries

In Part 2, we'll examine the features of various insert types. We'll also provide an informed breakdown of insert identification codes by character. This understanding will enable you to make the most informed insert selection for your application. Click on the button below to enroll.

Cutting Resistance and Turning Tool Selection Part 1

In Part 1, we dive into turning, exploring cutting resistance and tool selection. You’ll gain deeper insight into choosing the right tools and see how cutting conditions and tool geometry drive successful results. Click on the button below to enroll.

Basics of Turning Part 3: Tool Geometry & Clamping and Tool Holder Identification Code

In Part 3, we focus on tool geometry and clamping, covering the different types of holders and methods for securing tooling. We’ll then break down tool holder identification codes, letter by letter, so you can confidently apply this knowledge to maximize machine performance. Click on the button below to enroll.

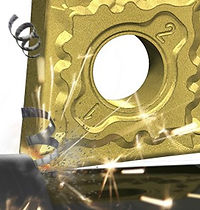

Cutting Resistance and Turning Tool Selection Part 3

In Part 3, we’ll explore the critical role of honing, followed by a deep dive into chip control and the key factors that influence it. The session will wrap up with an overview of surface finish and the variables that impact its quality. Click on the button below to enroll.